Not creating a route where water can exit your air conditioner or humidifier will cause major problems. The water drips on the floor, which, for example, can be dangerous if you have kids or electronics around. Luckily, a condensate pump solves that problem.

It sends water into your thermostat, thereby regulating its temperature. That water is converted into steam which cools down into acidic water that’s returned to the condensate pump.

However, what happens when a condensate pump runs nonstop? Not to worry, there are a couple of ways to fix a condensate pump running continuously without inviting a professional, and we will walk you through it shortly.

The job of a condensate pump is to extract condensation from your HVAC system – this could be a dehumidifier or Air conditioner. After a while, this condensation cools down and turns into moisture. Without a pump attached to your HVAC at home, you would have your indoor space flowing with water.

But why does the water need to be condensed in the first place? Well, it’s simple. The temperature of your AC heats up during the summer. The condensate pump sends water into the system to regulate its temperature. As its temperature drops, it produces steam which transforms to water when it cools down.

This contaminated water flows back to the condensate pump and is evacuated into drainage or an underground passage. The water sent into the HVAC system by the pump is often cleaner than the one coming through the outlet.

If no route is provided for the escape of this liquid, it drips on the ground and wets the floor. Unfortunately, this isn’t healthy since this water is acidic.

For a condensate pump to function well, it should be able to pump water into the HVAC system and, at the same time, provide a convenient route for the condensed steam to return to the pump.

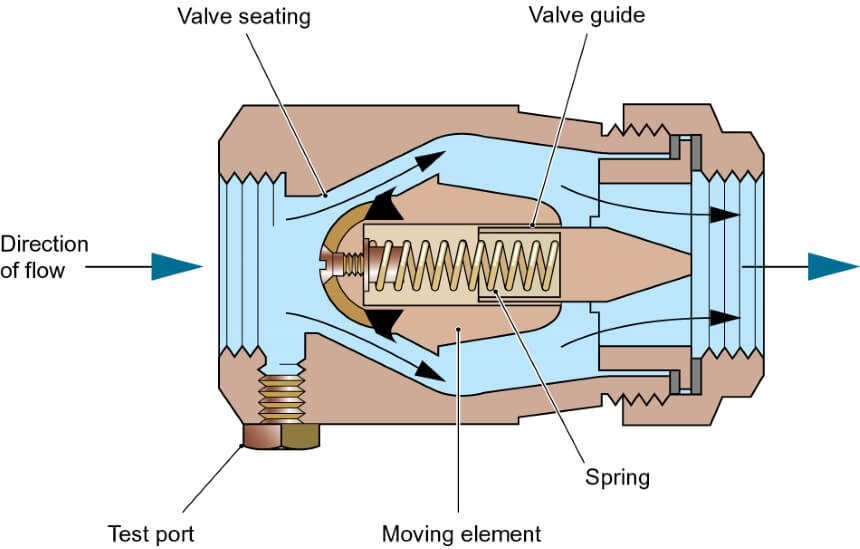

A typical condensate pump is made of a motor and an impeller. The motor is responsible for forcing water up to HVAC to regulate its temperature. A discharge line serves as the exit route and is connected to a ground storage.

If every condition is met, a condensate pump will continue to work when there’s a need to regulate the temperature of your thermostat.

However, if your condensate pump won’t shut off, several things might be behind it. The next section provides some common reasons why your condensate pump might not shut off and how to troubleshoot this

If you find your heat pump running constantly, there are possible factors responsible for it. In forums, we’ve seen questions such as “why is my condensate pump running continuously and what can I do to stop it.”

Well, if this is the case, you will be glad to know that some of these issues can be sorted out without inviting a professional. From experience, here are some of the reasons your heat pump might refuse to shut down.

For your pump to run smoothly, proper airflow is needed. The filters can’t be clogged; otherwise, fresh air will be prevented from coming in. Hence, the heat pump Trusted Source At home with a heat pump: ‘It makes hot water when it’s freezing outside’ | Energy bills | The Guardian Four householders with recently installed air source heat pumps discuss the ups and downs of ownership www.theguardian.com will run continuously when the air filter is clogged. If you sense that the filter is clogged, ensure you call a repairer to come in and fix the problem. Most of the time, a replacement will be needed. However, if you carry out periodic maintenance checks, the problem will be detected early on.

It’s difficult to detect a check valve issue. However, one of the likeliest clues is if the water level of the pump climbs up after the condensate heat pump has been shut down.

The check valve can be in order, and your condensate pump will still be working incessantly. Well, if that’s the case, you will have to run a thorough check on the discharge line. The discharge line is a flexible tube that connects the condensate pump to drainage.

If water is continuously getting held in the discharge line, it might cause the problem of a running pump. You want to ensure nothing clogs the discharge pump, which might prevent the water from exiting. If that’s the case, you will have to empty the content in the discharge line into a bucket to troubleshoot it.

Below are recommendations on how to fix a constantly running condensate pump, depending on the reason, and some way to prevent it from happening in future.

If water is trapped in your discharge line, you will have to empty its content by unplugging the condensate pump. You will have to pull out the discharge line with a hose clump before emptying the water into a bucket.

Once the water is emptied from the drain line, you can blow in some air into the discharge line to see if there’s any object clogging it.

The check valve and the discharging line somehow works hand in hand. Most of the time, when water is trapped in the discharge line, the check valve ensures the water doesn’t return to the condensate pump. This way, it turns the pump back on, prompting it to work endlessly.

To rectify the check valve, you will have to unscrew the condensate pump, especially if it’s screwed to a wall. Because of the strenuous task involved, we advise you to let a professional handle this task.

The handyman will remove the compensate pump from the wall and fill the inlet hole with water before fixing it to a GCFI outlet. The pump will send the water out of the check valve with some strong wave of current.

It’s important to clean every part of your condensate pump heater in addition to the valves. Over time, debris and algae might clog the discharge line. Once in a while, ensure the valves are removed and cleaned before re-installing. This minimizes clogging issues.

Almost every hardware experience faults from consistent usage, and the condensate pump machine isn’t exempted. As a general rule, frequent checks and maintenance help you nick any issue in the bud. Some of the most likely challenge users of this type of machine complain about is clogged valves, slow water discharge and pumps running continuously.

To minimize these problems, here are some precautions to put in mind when using a condensate pump.

We hope after reading this when next you find your condensate pump running continuously, you should be able to identify the problem and solve it. Periodic maintenance should be conducted to ensure your pump is always in good condition. This way, you don’t have to call a repairer all the time, and the life expectancy of your machine will be prolonged.

When it comes to compatibility, it’s always important to consider the height of the discharge line. Gravity influences how quickly water runs to the top of the pump and how fast it travels down. The longer the discharge line, the more power your pump needs to employ to get water down.