The air ducts are key elements in the process of how air conditioners or climate control systems work. It’s through the ductwork that the air treated is recirculated or distributed between the conditioning device and conditioned spaces. The duct materials must have certain pre-established limits, relative to the available space, noise level, speed, pressure drops, heat losses, leaks, or gains.

Regarding the type of material with which they are built, the ducts can be made of sheet metal or fiberglass. Although there are more flexible materials, our focus in this fiberglass duct board vs sheet metal article would be between these two materials.

There are circular, rectangular, and even oval ducts. Its constructive characteristics, such as sheet thickness, reinforcements, joints, dimensions, and even supports are standardized by national and regional associations. For example, the thicknesses of sheet metal ductworks are regulated by the Sheet Metal and Air Conditioning Contractors (SMACNA) and the European standards UNE-EN 1505.

The characteristics in terms of insulation and water tightness for air conditioning installations are usually included in the specific regulations.

It must be taken into account that the air pressure in the duct is the one that must determine the structural resistance and the tightness to leaks, while noise, vibrations, and friction losses depend, above all, the speed of the air.

The circular ducts are manufactured in smooth sheet metal with flanges and with measures of up to about 900 mm in diameter. The helical tube made from galvanized sheet metal strip, spiral seam, and plug-in modules, which is manufactured in internal diameters from 80 to 2000 mm is more common in facilities.

Since metal is a thermal conductor, sheet metal conduits must be thermally insulated. Usually, the material used consists of glass wool blankets to be placed on the outside of the duct. These blankets incorporate an aluminum lining that acts as a vapor barrier. This type of duct is ideal for indoors or outdoors since it avoids condensation and the loss of cold or heat from the air. Glass wool blankets with a glass fabric can also be placed inside the duct that allows acoustic absorption by the wool and reinforces the interior of the duct.

The sheet metal ducts are ideal for business or local supermarkets, but can also be adapted to housing. To know if your house is suitable for installing ducts, you must take into account several aspects, especially that the ceilings have a height that allows them to be placed, without posing a problem.

One of the downsides of metal sheets is their proneness to humidity and they are attraction materials for mold. Fortunately, you can have the material well-insulated from the outside, hence, ensuring humidity control and preventing mold growth. One of the most reliable insulating materials for sheet metal ducts is the R-8 HVAC Duct Wrap from AES. This insulation material has a foam core, is two-sided, and has a length of 100 square feet.

In addition, these ducts offer the advantage of lightness, good behavior against fire, and have excellent characteristics as an absorbent and acoustic attenuator. Of course, with this duct, there’s no need for extra insulation, since the fiberglass itself performs this function.

Its great drawback is the aesthetic one. They are not very suitable for exposed installations. However, they are widely used with ducted air conditioning installations for false ceilings or covered with plaster simulating beams or construction elements.

Regarding the health problems that are sometimes attributed to this type of duct, there are industry standards that require that the materials used in their construction must be classified as non-carcinogenic. In addition, they must not facilitate microbial proliferation.

More and more residential and light commercial HVAC jobs are being installed using rigid fiberglass duct systems. And there are many reasons why this is a growing trend. When properly fabricated and installed, duct board systems deliver heated and cooled air efficiently, quietly, at design temperatures with minimal air leakage. It is that simple.

Another benefit is that fiberglass duct systems are easy to fabricate and install. The ducts are lightweight and changes can be made right on the job site.

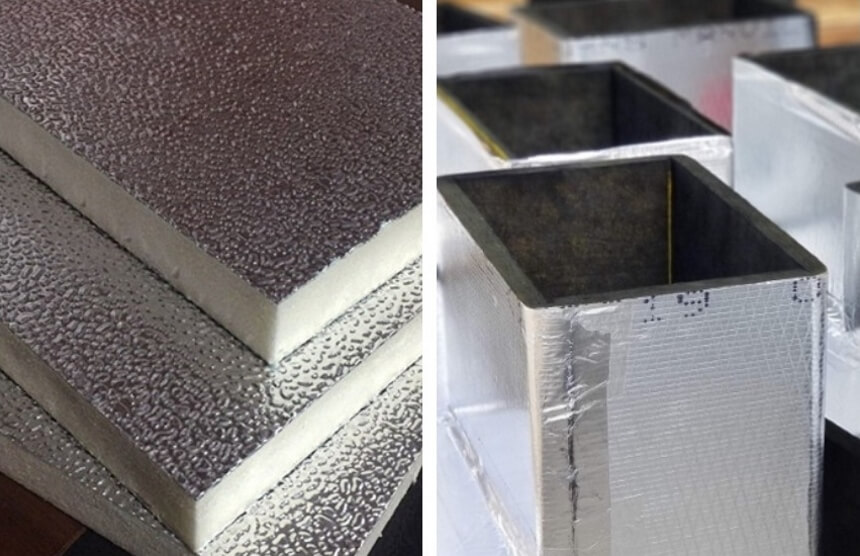

For those who have never worked with fiberglass duct boards, they are fabricated from 4 foot by 10-foot sheets of the fiberglass board. Each board has factory-formed male and female shiplap edges engineered to provide a method for joining.

One side of the board has an aluminum vapor retarder facing reinforced. This exterior surface also serves as the finish and provides the closure tab for duct joints.

The other side of the board is the air stream surface. These surfaces are tough enough for air movement up to 5,000 feet per minute without breaking down and stand up to duct cleaning if needed.

Fiberglass duct systems come in three thicknesses: one inch, one-and-a-half-inch, and two inches. The longitudinal joint when stapled and taped in place is like a Pittsburgh joint in sheet metal. It forms an airtight seam and holds the duct together.

One of the downsides of duct boards is that they’re complicated to fabricate or cut. However, there are tools to make things easier. For example, the Malco FG1 Hole Cutter can be used to cut fiberglass ducts quite seamlessly and precisely.

The finished duct meets the building codes and has the following advantages:

If you have decided to replace your ductless air conditioner with a type of air conditioning system for the whole house or one that you can vent, you need an air duct system constructed. Sheet metal and duct board have different properties and advantages.

Here, we’ll take a look at how different or similar both types of materials can be:

| Factor/property | Sheet Metal | Duct Board |

| Strength | Long-lasting and more durable | Stronger but has a good shelf life. |

| Airflow | The airflow properties are not excellent. Can cause proliferation of mildew and mold | Has better airflow. If the insulation materials are wrapped outside, mold and mildew won’t grow |

| Cutting | Easy to cut | Not as easy to cut; harder to fabricate |

| Noise | No noise issues | Can be noisy

|

The air ducts are the elements of an installation through which the air is distributed throughout the system. As its name indicates, air conditioning by ducts consists of a central console that distributes the air in channeling of pipes or ducts made of different materials which can be fiberglass or glass wool, sheet metal, or even flexible ducts.

Its material of construction largely determines the quality of the installation, as it plays a fundamental role in certain factors, such as energy use or its acoustic behavior.

In this duct board vs sheet metal comparison article, we explained how the two of the most common air conditioner duct construction materials – sheet metal and fiberglass – are made, tell you what their advantages and disadvantages are, and compared them side-by-side based on several characteristics.

Air ducts made from sheet metal plates (galvanized or stainless steel, copper, aluminum) can be easily cut and shaped to give the duct the necessary geometry for air distribution. However, fiber duct boards are the best in terms of airflow and preventing mold but can be noisy.